-

AboutThe quality assurance department of the company has formulated strict quality assurance system documents and organized front-line workers in various departments, offices and workshops to learn.

-

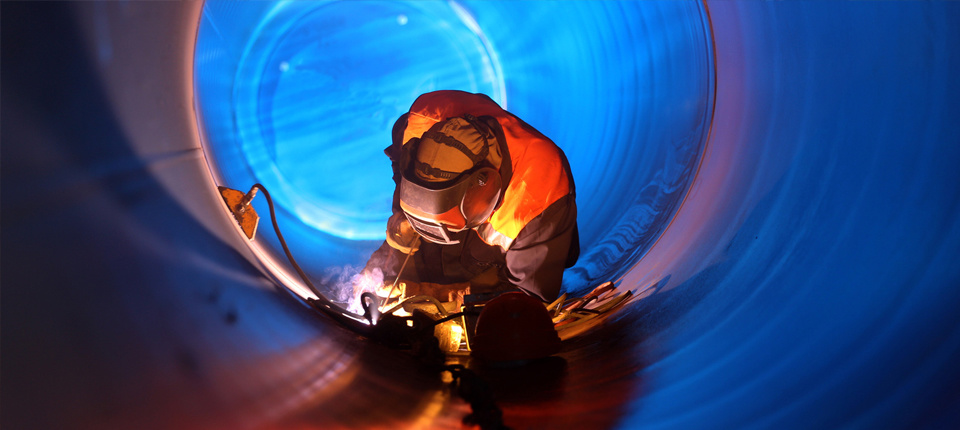

ProductsThe company produces 45000 tons of insulation pipes and pipe fittings annually. It has 5 internationally advanced polyethylene pipe production lines, and adopts internationally advanced screw die extrusion, vacuum sizing, spray cooling, automatic cutting and other processes, with an annual production of 20000 tons of polyethylene outer sheath pipe.

-

CaseThe company pays attention to talent training and talent introduction, and cooperates with Chinese Academy of Sciences Jiuzhang Technology Co., Ltd., Beijing Institute of Public Utilities Science, Beijing Institute of Coal and Heat and other scientific research institutes, colleges and universities, and constantly has senior technical personnel to colleges and universities for training and study.

-

NewsThe quality assurance department of the company has formulated strict quality assurance system documents, organized front-line workers in various departments, offices and workshops to study, and implemented a quality assurance inspection system based on self-inspection, mutual inspection between processes and final inspection by professional inspectors. Each process is produced in this process in strict accordance with the documents formulated by the technical department, and unqualified process products are not transferred to the next process. The rate of superior products has increased year by year.

-

ServiceThe company will take the domestic thermal insulation pipeline enterprise as its own responsibility, and continue to carry out innovation and product research and development to meet the needs of the majority of users.